Description

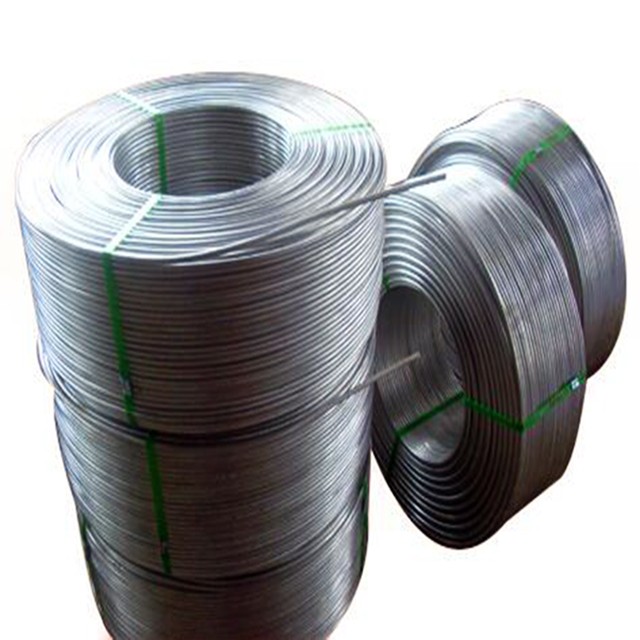

Shape and Packing:

1. Cut rod: Diameter is Φ9.5±0.3mm, 500-1000 mm long, 1 ton/pallet or wooden case

2. Coil rod: Diameter is Φ9.5±0.3mm, 185-210 kg/coil, 3 coils/pallet

3. small ingot: 25 kg/carton, 1000 kgs/pallet

Aluminum titanium carbon master alloy instructions:

Ⅰ. Performance characteristics:

Al-Ti-C grain refiner is high purity , withextremely less salt inclusions. It produces a large number of dispersal distributed TiAl3, TiC high melting point particles in molten aluminum. The grain structure is refined outstandingly in 3 minutes after Al-Ti-C grain refiner added, the yield strength and rolling plasticity of aluminum foundry products are improved obviously, meanwhile, reduce brittle-ductile transition temperature, lower rejection rate,improve comprehensive mechanical property, and appearance quality of finished products, enhance oxidation color uniformity and luminance of aluminum products.

Ⅱ. Range of application:

1. Al-Ti-C grain refiner is used for grain refinement of pure aluminum ingot and general aluminum alloys casting, it can gain less than 200μm isometric crystal with only 1‰ addition.

2. Al-Ti-C grain refiner is especially suitable for aluminum foil production, it can reduce pinhole degree and pin porosity of finished product effectively.

3. Used for aluminium conductive materials, Al-Ti-Cgrain refiner can decrease the electrical resistance and enhance the electrical conductivity effectively.

4. Al-Ti-C grain refiner performance is superior to other grain refiners/ master alloys when using in casting and rolling production line.

5. For aluminum alloys containing more than 3% of Si, the refining effect of this product is slightly weaker. By increasing the feeding amount, the refining effect can be effectively improved, and the mechanical properties can be improved by about 10%.

Ⅲ. Method of application:

1. Make sure keeping AL-Ti-C grain refiner clean and dry before feeding it;

2. Feeding temperature:700~760℃;

3. Feeding quantity: It’s recommended to add 2 KG of the AL-Ti-Cgrain refiner for per ton aluminum. Or It could adjusted by your experiment data, according to the real situation. Note: The weight of this product per liner meter is 200g ± 2g;

4. Feeding time: 5~20 minutes before casting;

5. Feeding method: (1) For 500 mm cut rod shape, push aside dross first, then put Al-Ti-C grain refiner into molten aluminum liquid uniformly and dispersedly, stir evenly, stay standing for 5~10minutes before casting. (2) For coil rod shape, It can be added on line by feeding machine. The feeding machine should be placed between the aluminum furnace water discharge port and the degassing box, 1.5~ 3 meters away from the degassing box;

6. The refining effect is beginning todecay after holding 30minutes, it’s needed tore-feed grain refiner once severe attenuation happens.