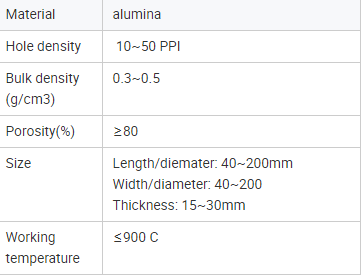

Description

It is made of high quality and high purity alumina. It is made of unique formula and advanced environmental protection technology.

It has uniform three-dimensional network structure, high strength, stable texture, no

slag, high temperature resistance and

thermal shock resistance. Strong and excellent performance. Mainly used in the purification process of aluminum and aluminum alloy production, also applied to various gas-solid,liquid-solid separation media,catalyst carrier,burner and sound-absorbing environmental protection.

Features

produced by 120 meters roller kiln, fully automated production line

High strength, no slag, good thermal shock resistance;

High porosity, small filtration resistance, high surface energy, heterophase adsorption capacity, no pollution to molten aluminium

good stability when molten aluminium pass

various specifications, can provide 7-inch to 26-inch also can be customized according 20PPI to 70PPI;

Three different types of sealing gasket: fiber paper , fiber cotton and expandable

Advantages

Use more 4-5 times than other CFF in case of Electrical heating 1.26Mpa compressive strength higher than other CFF 0.6-1MPa

Usage

1. Clean the filter box before use a filter

2. Gently place the CFF into the filter box slot and press the sealing around to prevent side flow.

3. Uniformly preheat the filter box and CFF to make them close to the molten aluminium temperature

4. preheated by electric or gas Under normal circumstances: 15-30min.

5. make launder full of molten aluminium during filtration, avoid striking and vibrating

6. After the filtration, take out the filter plate in time and clean the filter box.