Description

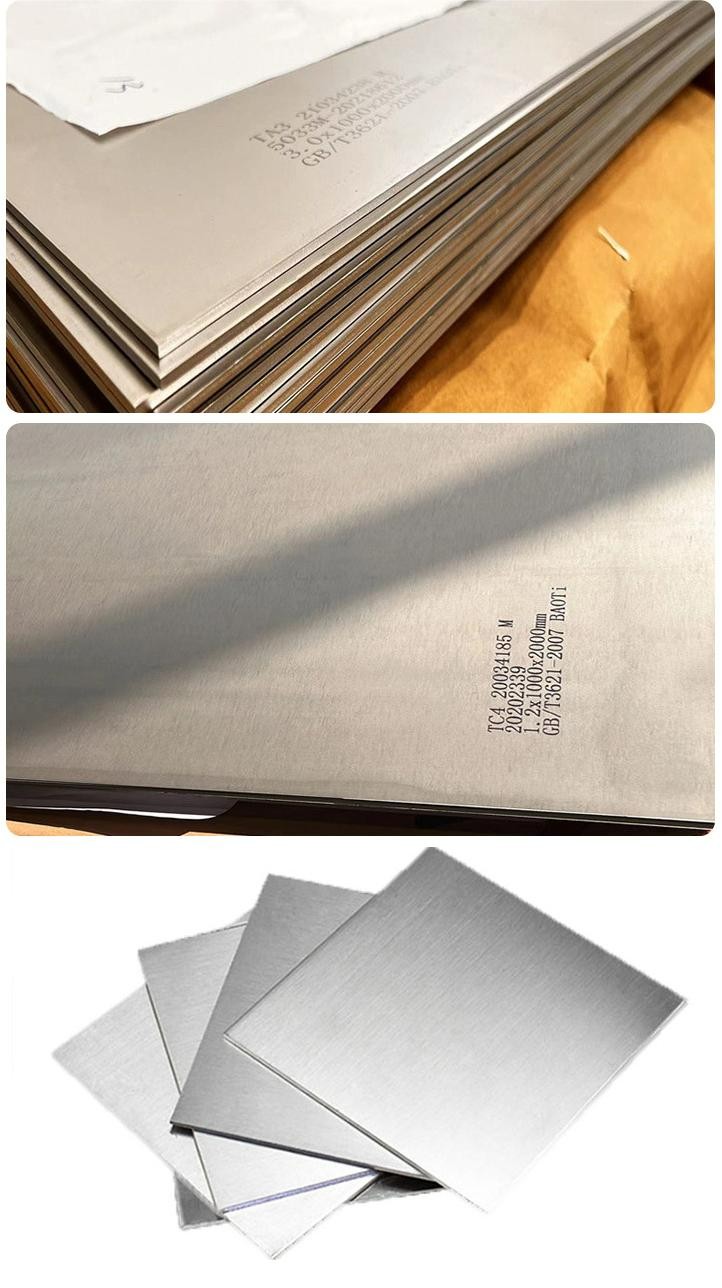

Titanium plate (Ti Plate)

Basic Grade:GR1、GR2、GR3、GR5、GR7、GR12; BT1-00、BT1-0、BT1-2; TA0、TA2、TA3、TA5、TA6、TA7、TA9、TA10、TB2、TC1、TC2、TC3、TC4

Standard: GB/T3621-2007、GB/T13810-2007; ASTM B265、ASTM F136、ASTM F67、AMS4928

Supply State:Cold Rolled (Y), Annealed (M); Hot Rolled (R), Annealed (M)

Titanium plate material and performance

TA1 pure titanium is an unalloyed, low-strength titanium product with low oxygen content and high formability; this titanium material is used in fuselages, heat exchangers and desalination units.

TA2 pure titanium is an unalloyed medium strength titanium material. Good weldability and corrosion resistance are its notable features.

TC4 Titanium Alloy (Ti-6AL-4V) is an alloyed titanium product containing 6% aluminum and 4% vanadium; it is a medium strength titanium alloy. This grade of titanium is primarily used in airframe and turbine engine parts; and in surgical implants.

TA9 (titanium-palladium alloy) (Ti-0.2Pd) has excellent corrosion resistance in oxidizing media. It also has a certain corrosion resistance to reducing media, especially to improve its crevice corrosion resistance in high chloride ion concentration media.

TA10 (titanium-molybdenum-nickel alloy) (Ti-0.3Mo-0.8Ni) is a titanium alloy resistant to crevice corrosion. The tensile strength of the alloy at 300 is twice that of pure titanium, and its corrosion resistance to reducing media is obvious. Improvement, crevice corrosion does not occur in 150-200 chloride.

Compared with Ti6Al4V, TA15 (Ti-6.5Al-1Mo-1V-2Zr) has higher room temperature and high temperature strength, fracture toughness, fatigue limit, stress resistance, corrosion resistance and welding performance.

Titanium plate application

Heat exchangers, pressure vessels, water treatment, seawater desalination, chemical industry, petrochemical industry, machinery, automobile, aerospace, medical equipment, accessories and other fields